Capabilities

Why CTR: Built Fast. Built Right. Built to Perform.

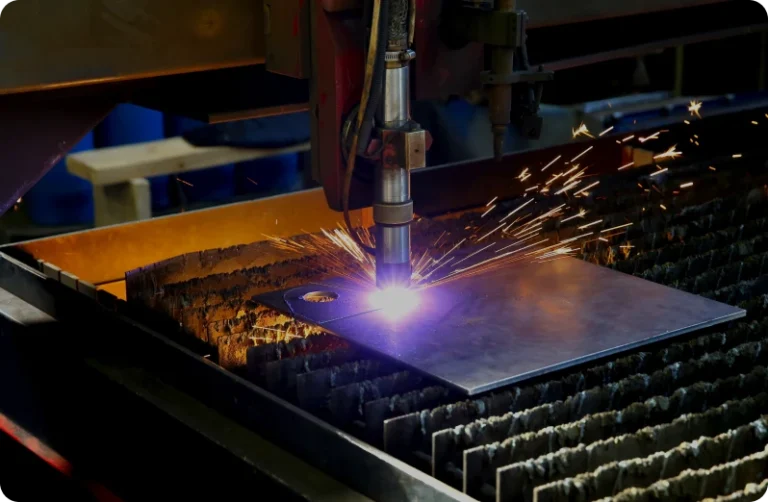

CTR’s fabrication services aren’t just about machines; they’re about people who care about getting it right. Our shops aren’t built to meet industry benchmarks; they set them.

Whether you need metal fabrication, treated lumber and CCA lumber components, custom fiberglass fabrication, or turnkey cooling tower solutions, we deliver speed, precision, and durability built to last.

We double-check quality at every step to ensure what arrives on-site performs is exactly what you ordered. With over 30 years of fabrication services expertise and one of North America’s most advanced machinery lineups, we’re built to solve problems others can’t. From cooling tower upgrades to complete cooling tower fabrication projects, our fabrication and assembly capabilities handle projects of any scale.

Our comprehensive custom fabrication services include everything from precision machining to complete cooling tower fabrication.

Why clients choose CTR:

Precision: CNC fabrication systems calibrated to your exact drawings

Flexibility: Wood, fiberglass, metal, and hybrid solutions, including fiberglass structural shapes and fabricated structural grade lumber

Speed: Rapid turnaround, including same-day and 48-hour options

Quality: Treated lumber, tested, and built to outperform

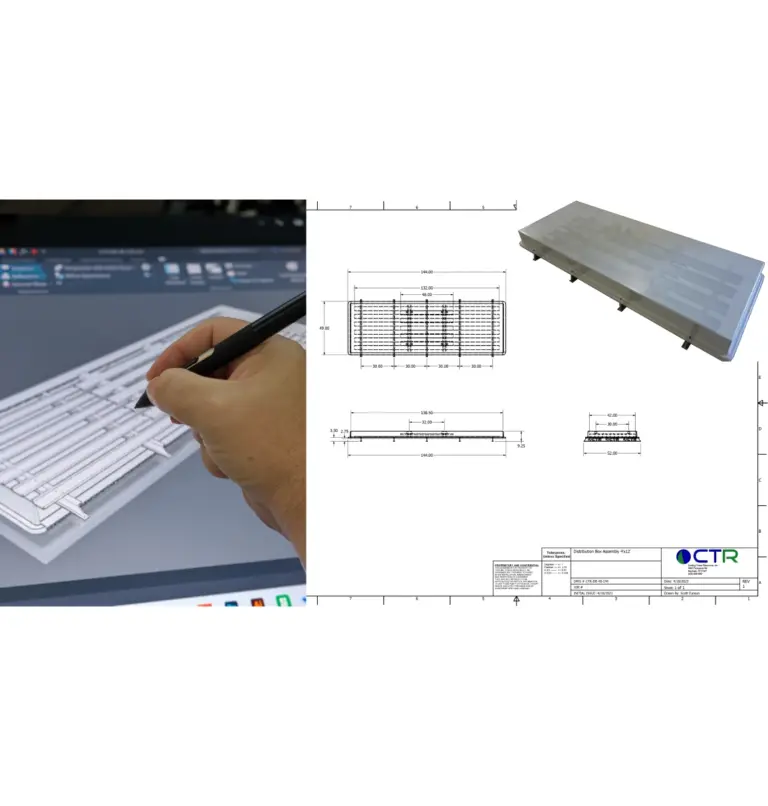

Design Engineering: From Sketch to CNC Reality

From napkin sketch to machine-ready code, our design team brings your concept to life with speed and precision. Whether you’re modernizing old plans or starting from scratch, we take your drawings to life and make fabricated lumber, metal, and fiberglass a reality.

Need PE stamp services? We can coordinate with licensed Professional Engineers (PE) to provide a PE stamp when required for your fabrication services projects.

Our design staff works directly from PDF files, hand-drawn takeoffs, or full AutoCAD (.dwg, .dxf) files, converting them to clean G-code for CNC fabrication. We support 3D models, nested cutting, and reverse engineering for both complex cooling tower fabrication systems and one-off jobs.

Our in-house custom nesting software minimizes waste, saves time, and ensures consistency across high-volume CNC fabrication runs. Whether you need iterative prototypes or a fully specced production order, we’ll get it fabricated right, and fast.

Custom Fabrication: No Templates, Just Tailored Solutions

When off-the-shelf solutions won’t suffice, we fabricate to your exact specifications. Our custom fabrication services support projects of all sizes, from intricate components to massive cooling tower fabrication structures. We specialize in the fabrication of cooling tower torque tubes, including their galvanizing process, as well as precision-engineered support systems.

Our CNC fabrication capabilities encompass a wide range, from wood and fiberglass assemblies to intricate metal assemblies.

Every fabrication and assembly project, when appropriate, benefits from our advanced processing and materials expertise which we apply to treated lumber, structural fiberglass, or metal.

We operate three router tables built for scale and speed:

- 10′ x 24′ MultiCam 7000 (large-format)

- 5′ x 20′ MultiCam 5000 (mid-size)

- 5′ x 10′ MultiCam 5000 (compact jobs)

From initial drawing to delivery, our CNC routers, vacuum tables, and TigerStop™ systems give us unmatched flexibility and accuracy. When we say custom, we mean it.

Quick Ship: When You Needed It Yesterday

At CTR, we’ve engineered our entire operation for urgency. Need same-day shipping? Done. Prefer will-call pickup? It’s ready.

When your team faces downtime, we move quickly, with no compromise on quality or precision.

From stocked inventory to rapid custom fabrication, our quick-turn process is designed to resolve issues before they escalate. Some orders ship within 24 hours. . If speed matters, we’re the ones you call.